Explore our machine virtually

Move the slider and click the info points for more information.

The right machine for your task

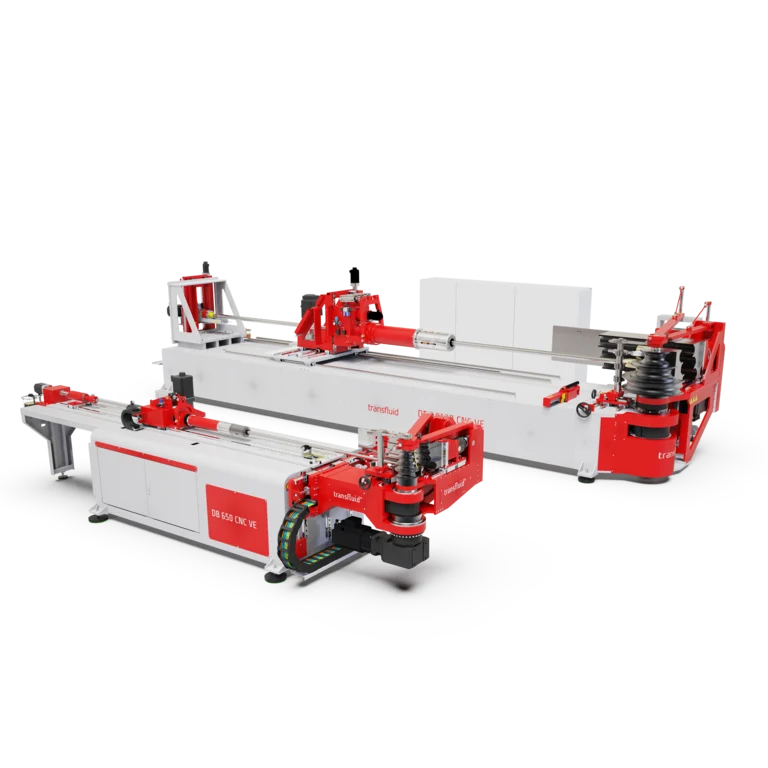

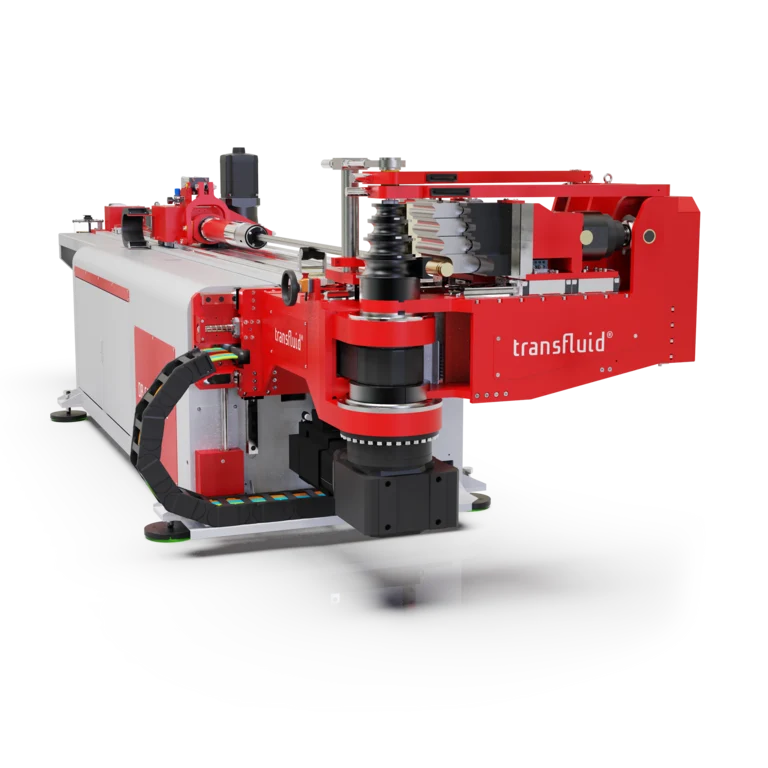

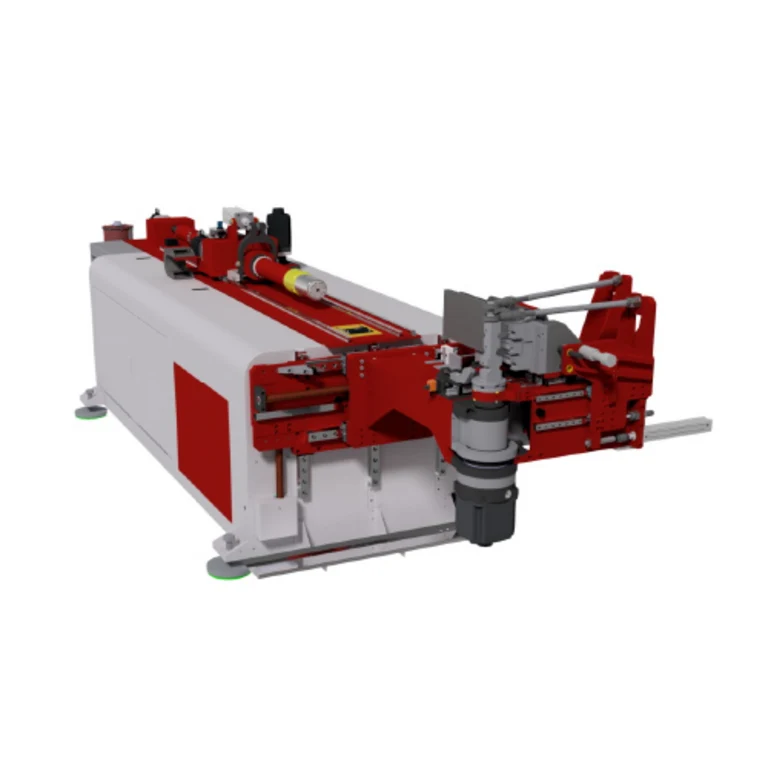

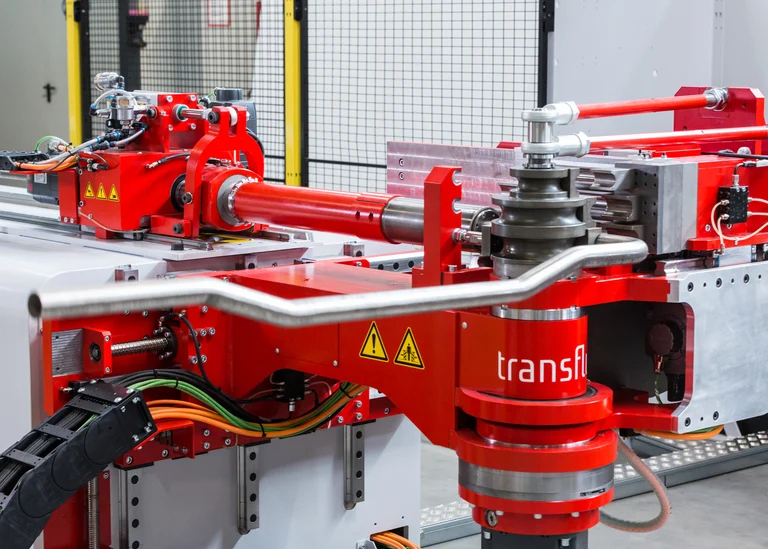

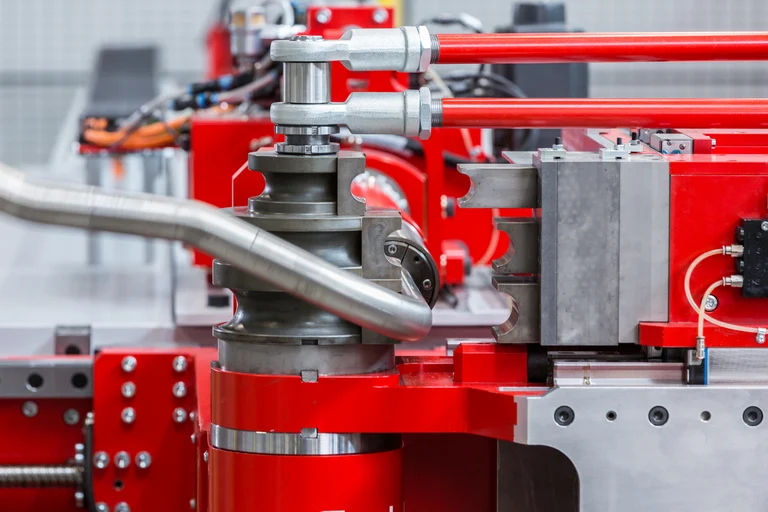

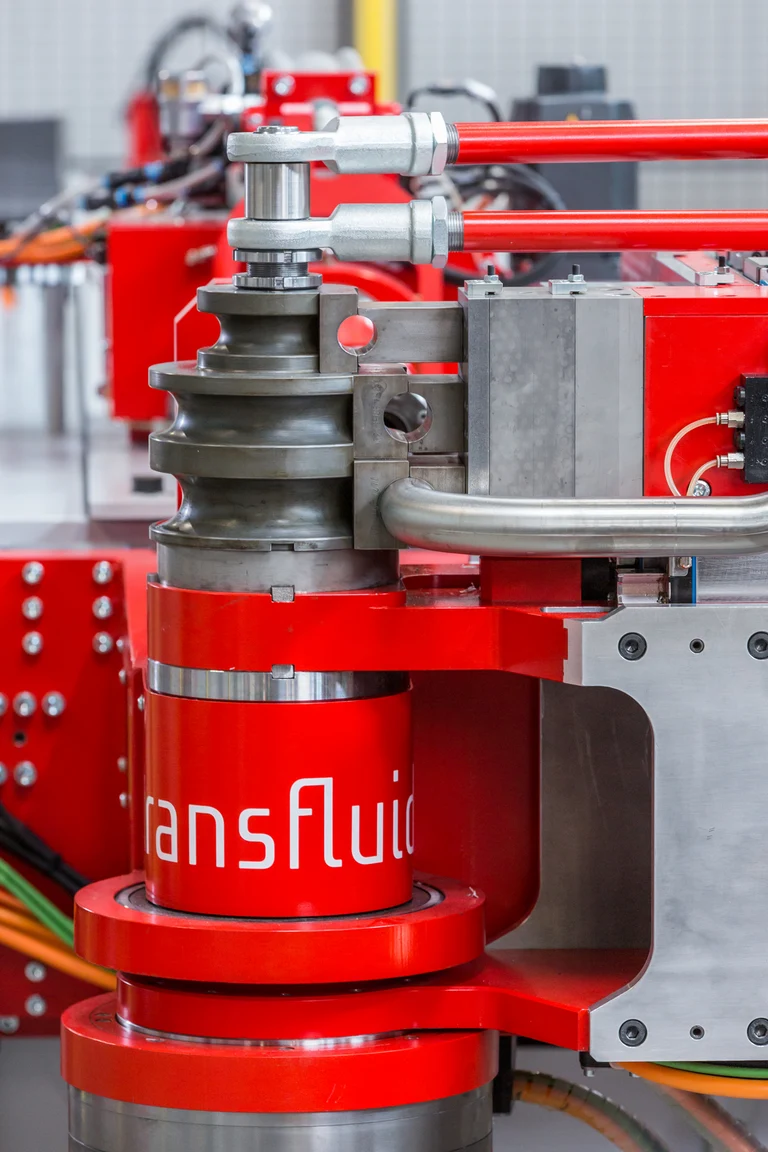

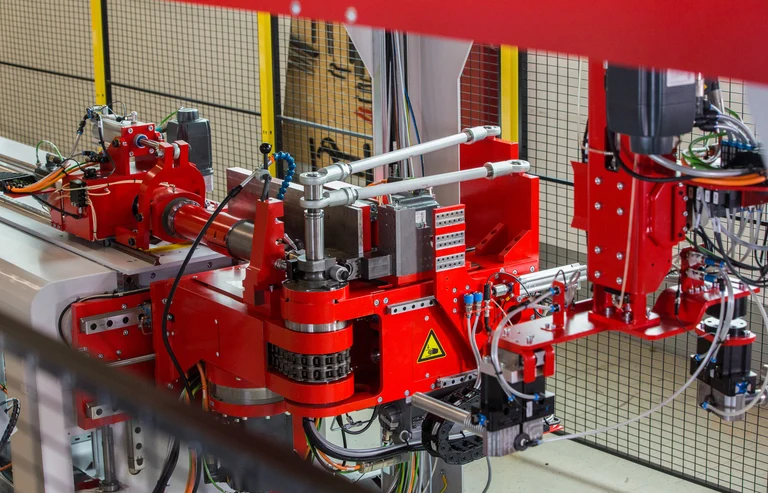

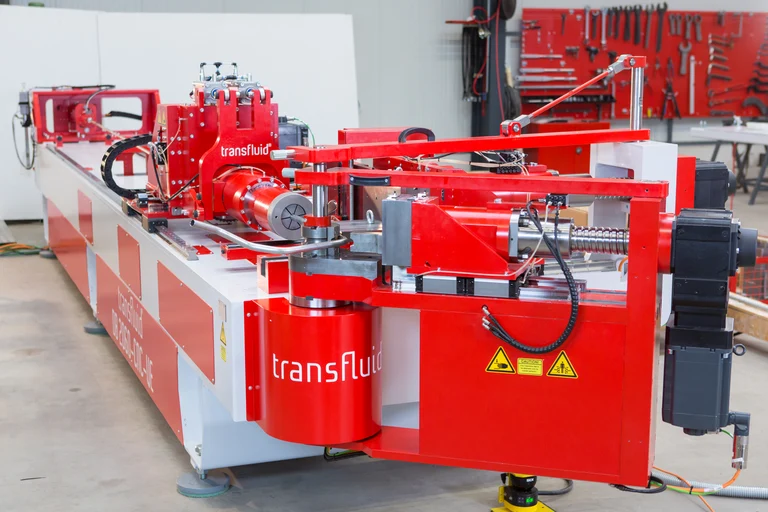

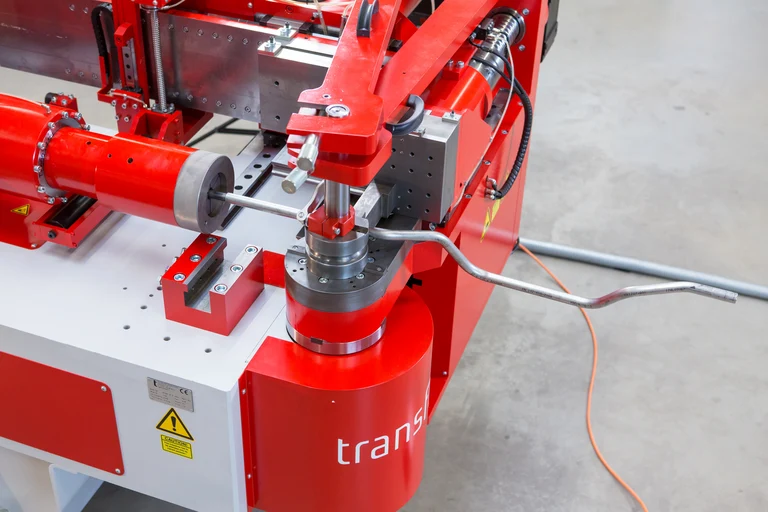

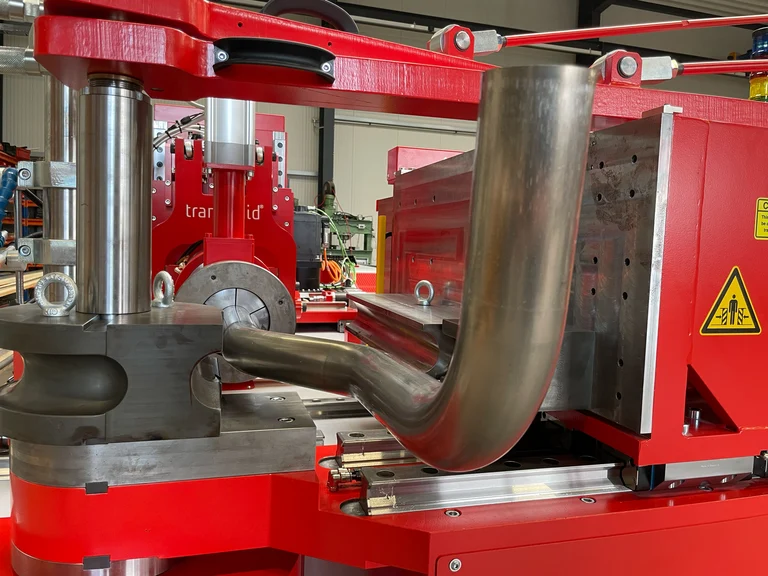

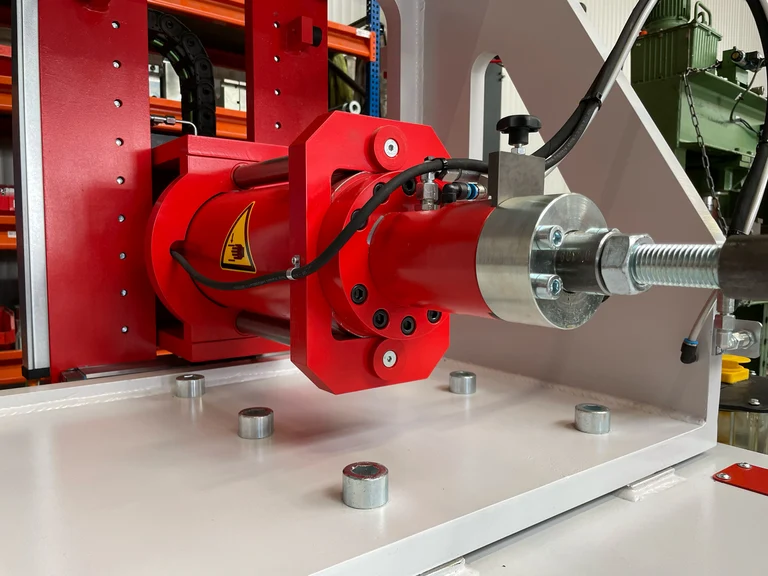

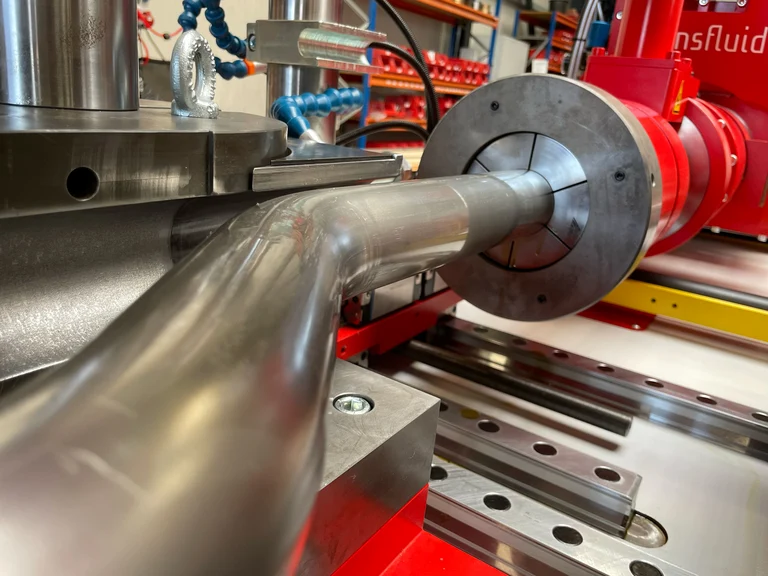

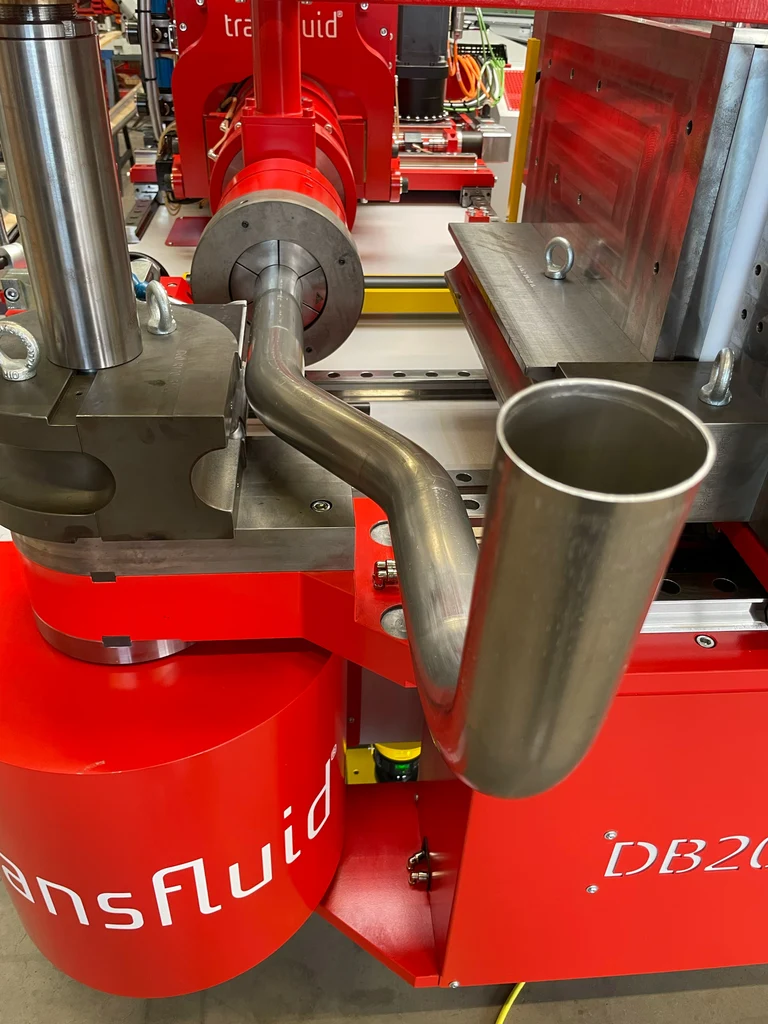

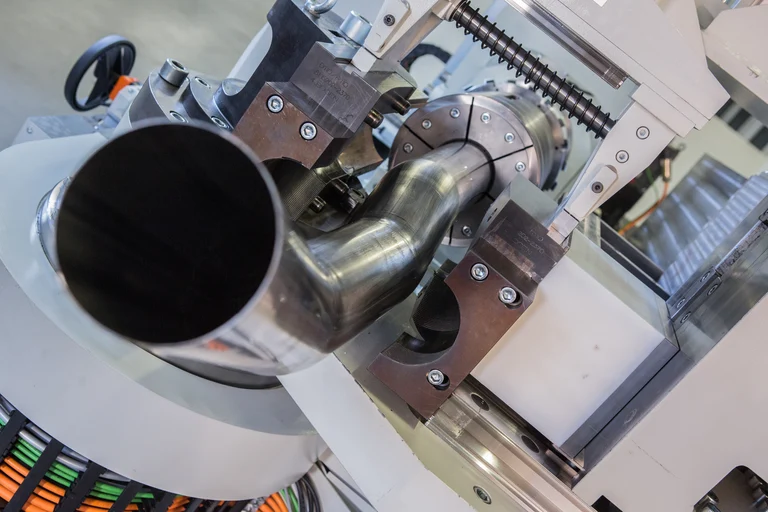

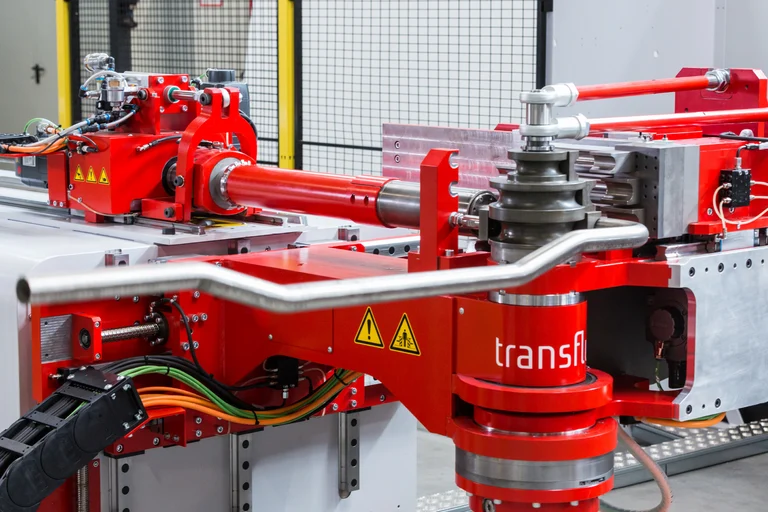

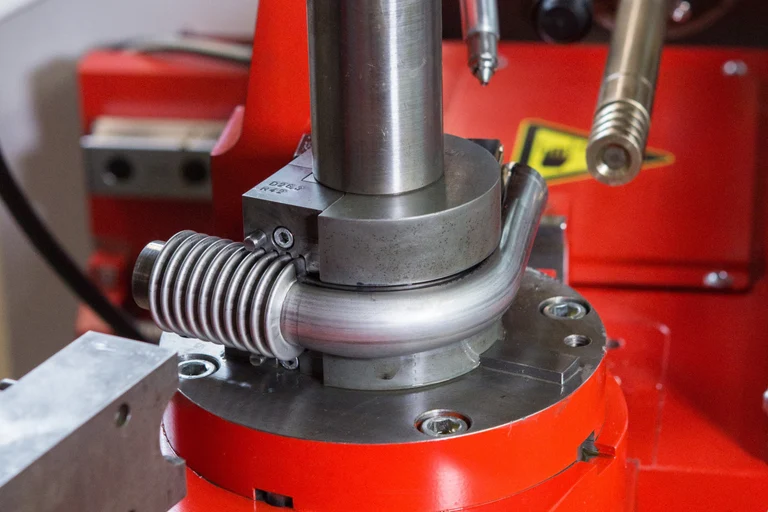

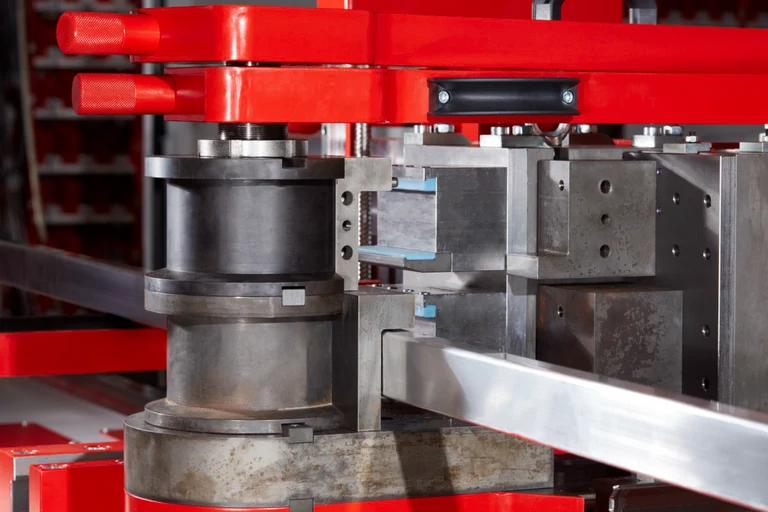

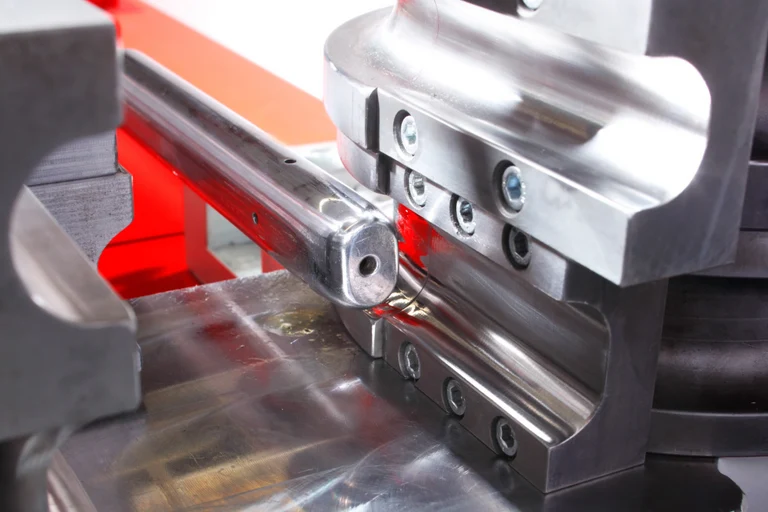

MANDREL BENDING MACHINES Full electric with CNC-Control

| Range | 6 - 22 mm |

| Max. capacity | 22 x 2 mm (mild steel) 22 x 1,5 mm (stainless steel) 16 x 1,5 mm (square mild steel) |

| Max. Radii | 66 mm |

| Usable length | 2000 mm (standard) 3048 mm 4572 mm 6096 mm (special) |

| Speed of bending axis | 300 °/sec. |

| Range | 6 - 30 mm |

| Max. capacity | 30 x 2 mm (mild steel) 30 x 1,5 mm (stainless steel) 20 x 2,5 mm (square mild steel) |

| Max. Radii | 90 mm |

| Usable length | 2000 mm (standard) 3048 mm 4572 mm 6096 mm (special) |

| Speed of bending axis | 275 °/sec. |

| Range | 6–42 mm |

| Max. capacity | 42 x 3 mm (mild steel) 42 x 1,5 mm (stainless steel) 25 x 2,5 mm (square mild steel) |

| Max. Radii | 168 mm |

| Usable length | 2000 mm (standard) 3048 mm 4572 mm 6096 mm (special) |

| Speed of bending axis | 180 °/sec. |

| Range | 6-50,8 mm |

| Max. capacity | 50,8 x 3 mm (mild steel) 50,8 x 2 mm (stainless steel) 35 x 35 x 4 mm (square mild steel) |

| Max. Radii | 150 mm |

| Usable length | 2000 mm (standard) 3048 mm 4572 mm 6096 mm (special) |

| Speed of bending axis | 180 °/sec. |

| Range | 6–60 mm |

| Max. capacity | 63 x 2,0 mm (mild steel) 63 x 1,5 mm (stainless steel) 35 x 35 x 4 (square mild steel) |

| Max. Radii | 150 mm |

| Usable length | 2000 mm 3048 mm (standard) 4572 mm 6096 mm (special) |

| Speed of bending axis | 180 °/sec. |

| Range | 6–80 mm |

| Max. capacity | 80 x 3mm (mild steel) 80 x 2 mm (stainless steel) 55 x 4,0 mm (square mild steel) |

| Max. Radii | 240 mm |

| Usable length | 3048 mm (standard) 4572 mm 6096 mm (special) |

| Speed of bending axis | 100 °/sec. |

| Range | 20–101,6 mm |

| Max. capacity | 101,6 x 3 mm (mild steel) 101,6 x 3 mm (stainless steel) 70 x 70 x 4 mm (square mild steel) |

| Max. Radii | 305 mm |

| Usable length | 3048 mm (standard) 4572 mm 6096 mm (special) |

| Speed of bending axis | 80 °/sec. |

| Range | 40 - 130 mm |

| Max. capacity | 130 x 3,0 mm (mild steel) 130 x 2,5 mm (stainless steel) 90 x 90 x 5,0 (square mild steel) |

| Max. Radii | 390 mm |

| Usable length | 4572 mm 6096 mm (special) |

| Speed of bending axis | 65 °/sec. |

| Range | 20-150 mm |

| Max. capacity | 150 x 3,0 mm (mild steel) 150 x 2,5 mm (stainless steel) 90 x 90 x 5,0 mm (square mild steel) |

| Max. Radii | 450 mm |

| Usable length | 4572 mm (standard) 6096 mm (special) |

| Speed of bending axis | 65 °/sec. |

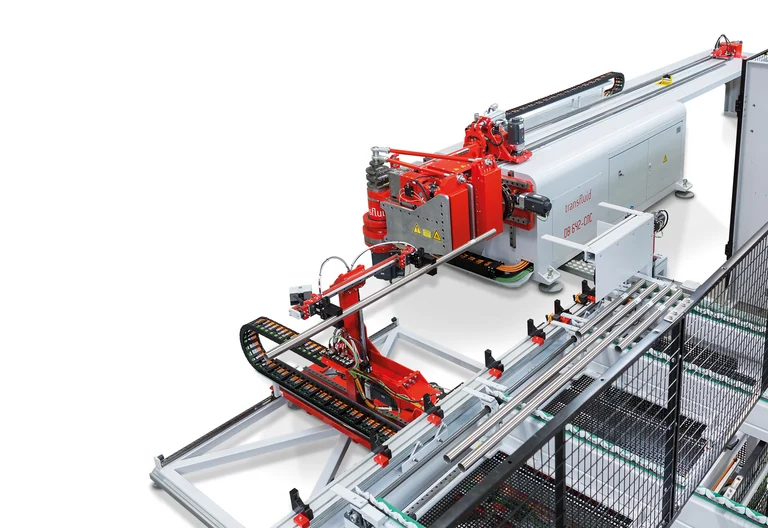

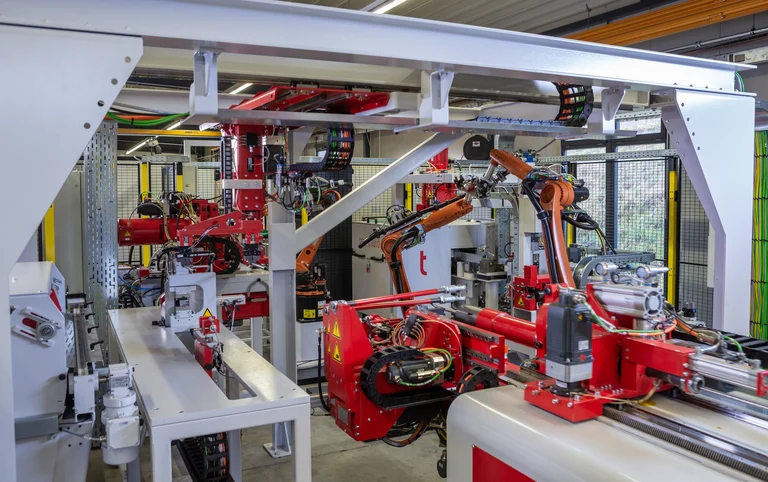

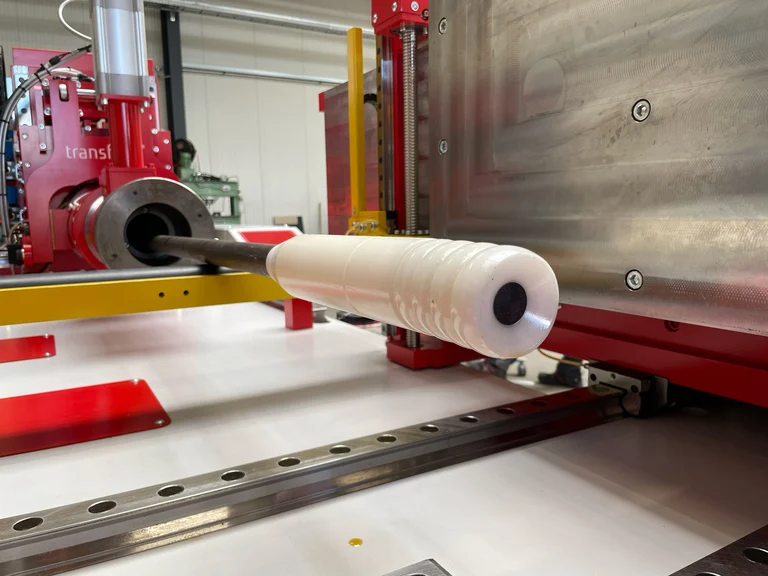

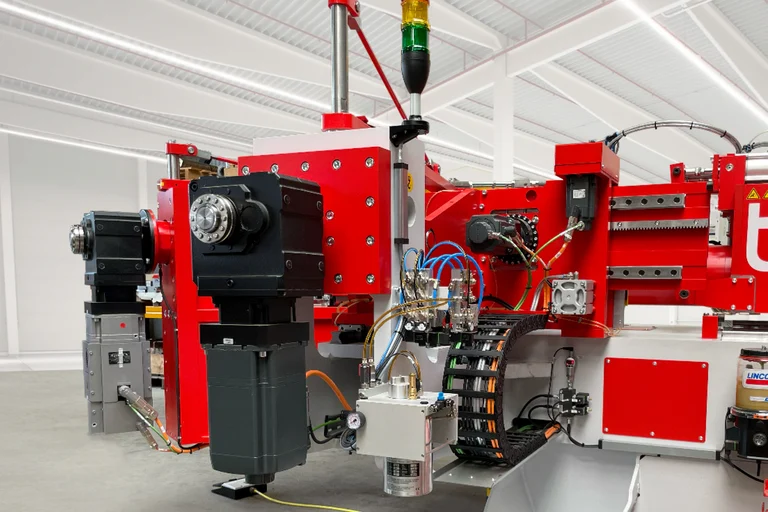

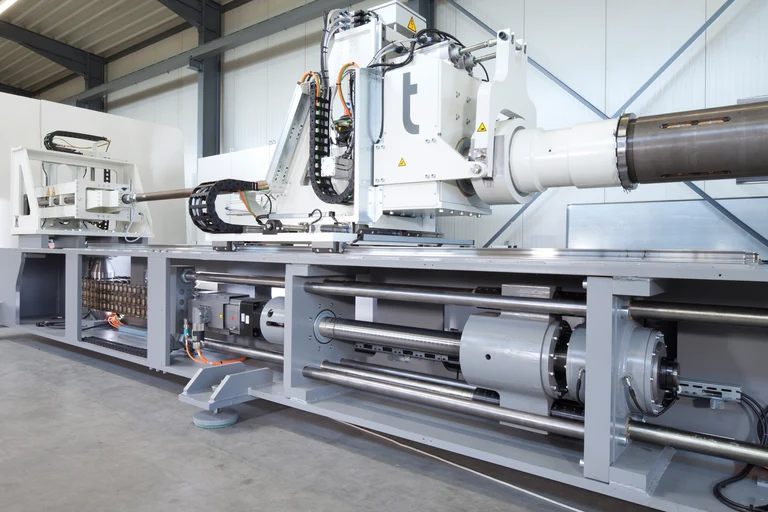

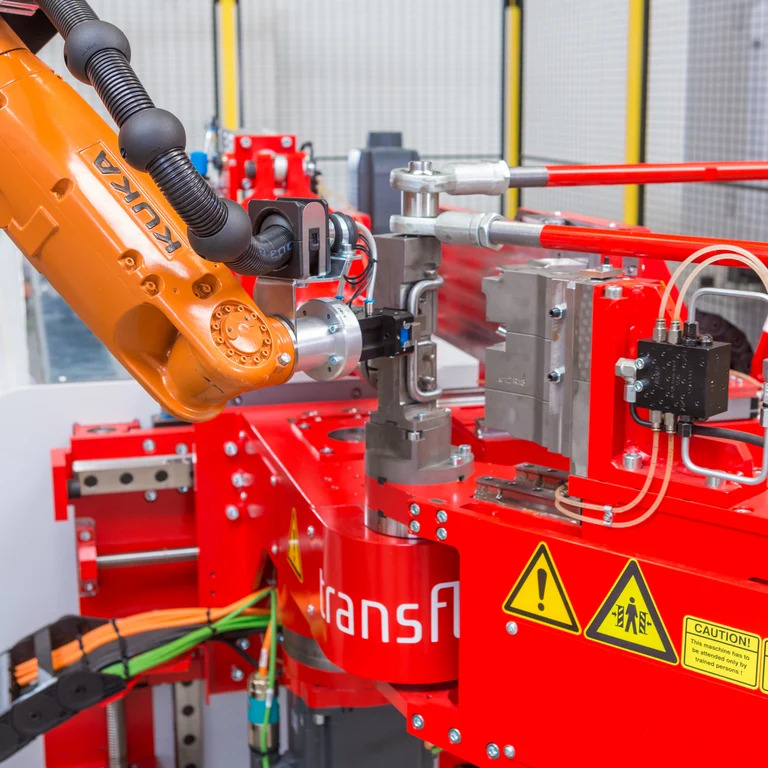

COST-EFFECTIVE MATERIAL LOADING

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible.

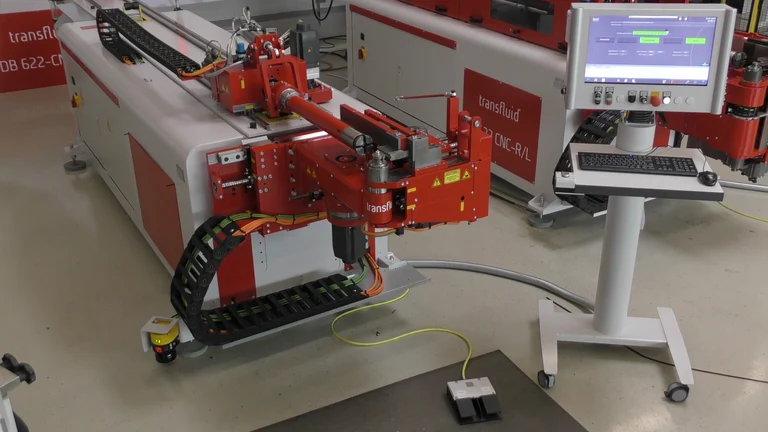

Powerful Software

Go directly from CAD to the tube bender with t-project tube bending software and upload functions. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100%. Easy programming from the desk, fast estimating of new projects, collision testing before running the machine and direct upload of the tube bending sequence to tube bender.

Catalog Download

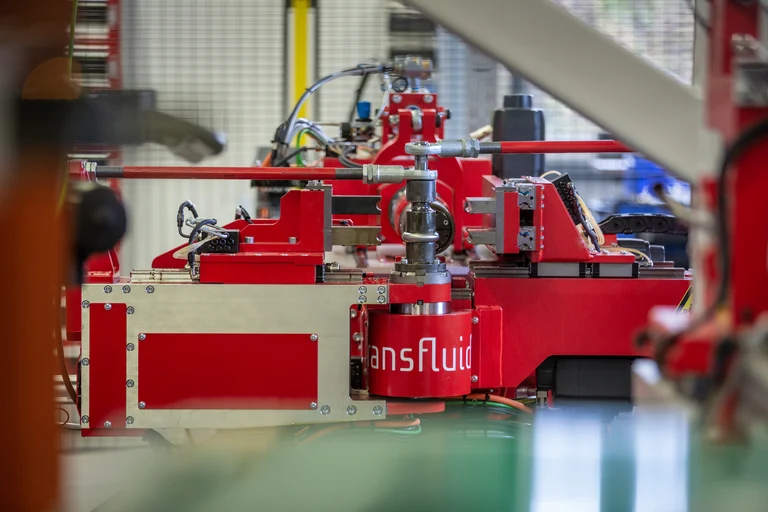

transfluid® offers the complete package for the production of tubing.

Download our new catalogue.