A german mechanical engineering company serving the global market

Your solution for bending and forming tubes, pipes and more in the most efficient way - with transfluid.

transfluid® THE SOLUTION FOR TUBES

With transfluid®, you bring high end technology to your production. Our solutions, services and systems are attuned to what you need to produce on the world market level. For your requirements and even more complex challenges, for individual units or serial production in consistently high quality – with custom, high-tech developments or our high-performance machine standards: transfluid® has the solution to advance your ideas.

-

Bending machines

High-tech to achieve the best results with unlimited bending possibilities.

See all -

Forming machines

Tube forming machines to get your ideas in top form.

See all -

Mobile tube benders

Mobile and compact tube bending machines.

See all -

Cutting machines

Pipe cutting machines for impressively clean cutting results.

See all -

Automation solutions

Automation for an ideal production flow.

See all -

Software

Software: virtual support for greater efficiency.

See all -

Robotic bending technology

Maximum bending freedom.

See all

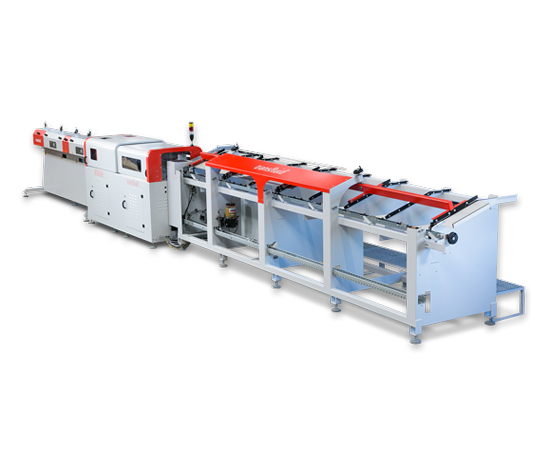

transfluid® Mandrel Bending Machines

for Exhaust, Headers and Accessories.

The DB 20101 mandrel bending machine can now be controlled easily with a touch panel. This opens up new possibilities, like displaying the comparison of target and actual values for all axes.

The machines are extremely robust and easy to operate. A selection of setups is available to process tubes of different lengths, with an operational length up to 240“

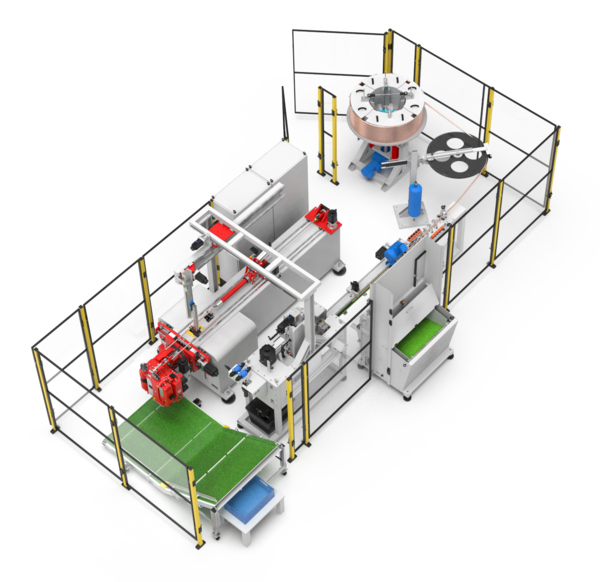

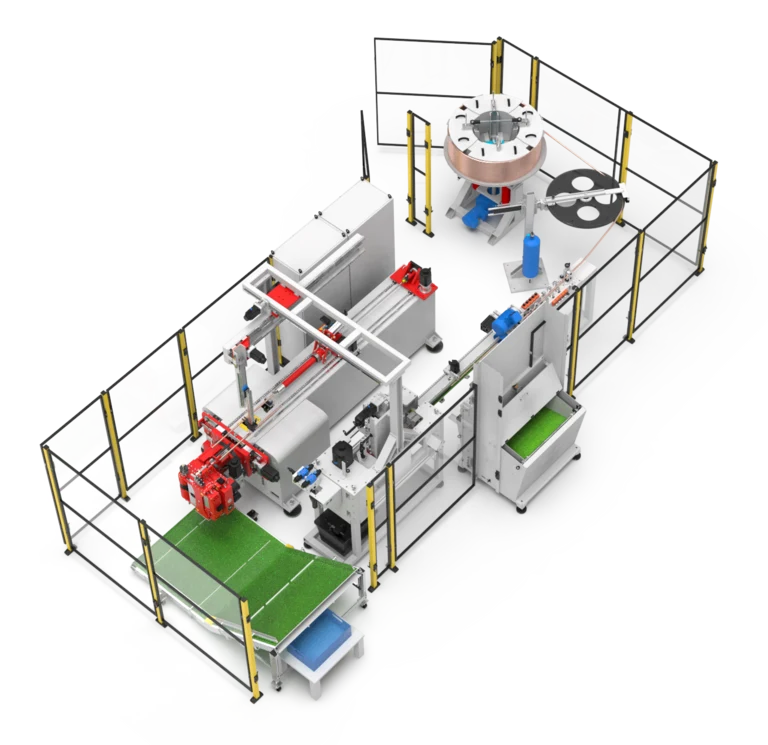

TPC 628:

Compact manufacturing cell concept for

fully automatic tube production

Due to the current demand in the field of renewable energies, especially with regard to heat pumps but also for domestic hot water systems, we have decided to create a new, particularly compact production cell concept that is specially adapted to this field and offers customers a capacity expansion at a good price/performance ratio with the smallest possible space requirement.

Our Team of experts is here to help

The excellent 24-hour after-sales service fromtransfluid® also guarantees particular sustainability of our solutions. Service Manger Christoph Aldrian and his team are there for you. They provide fast, effective solutions for optimised performance.