SUPPLY TECHNOLOGY The specialist for tube bending and tube forming in the field of HVAC

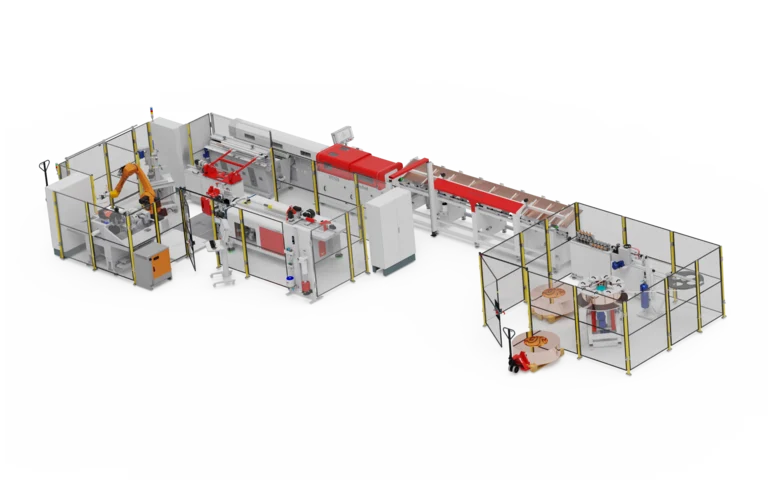

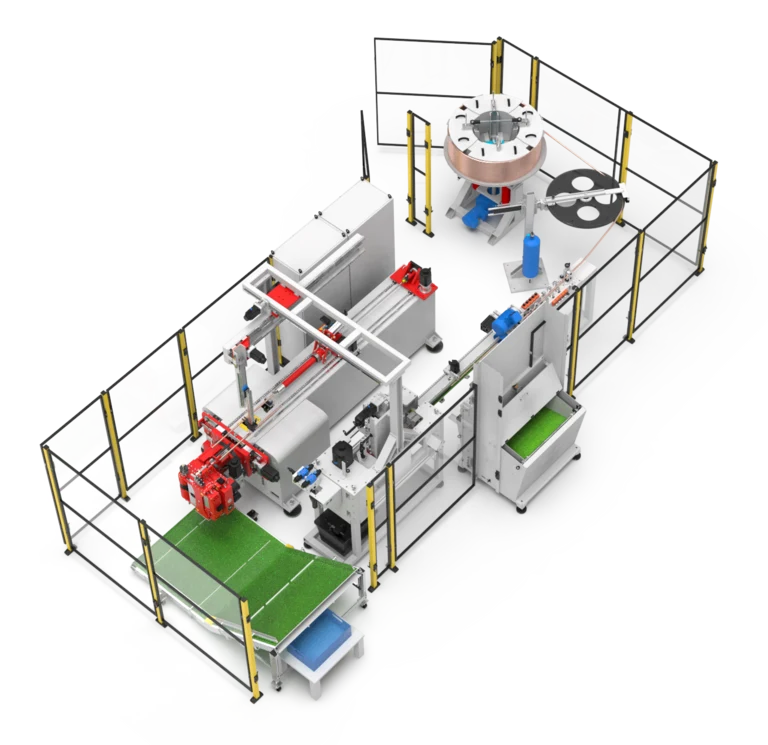

Fully automatic complete solutions for all areas of pipe processing

Connections can be formed directly on the pipe end

Software solutions perfectly adapted to the applications

Extremely short setup times

Robot integration of all common brands (KuKa, ABB, Yaskava, Fanuc, etc.)

Laser cutting systems from Trumpf

TPC 628: Compact manufacturing cell concept for

fully automatic tube production

Due to the current demand in the field of renewable energies, especially with regard to heat pumps but also for domestic hot water systems, we have decided to create a new, particularly compact production cell concept that is specially adapted to this field and offers customers a capacity expansion at a good price/performance ratio with the smallest possible space requirement.

Catalog Download

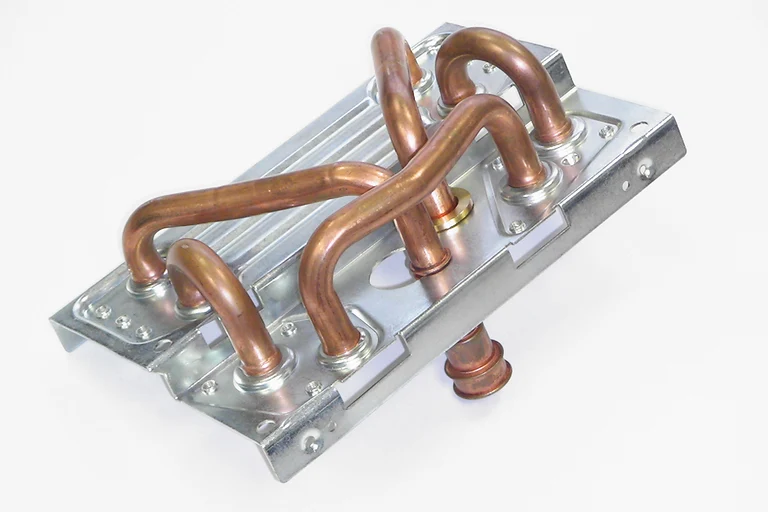

transfluid® offers the complete package for the production of tubing.

Download our new catalogue.

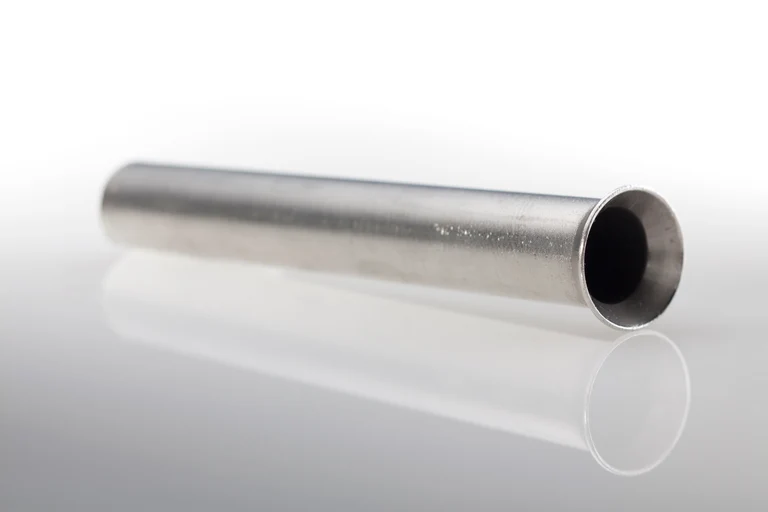

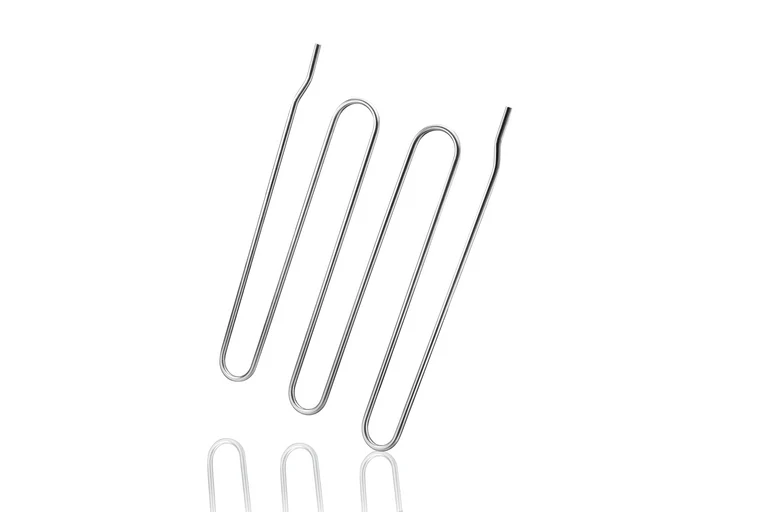

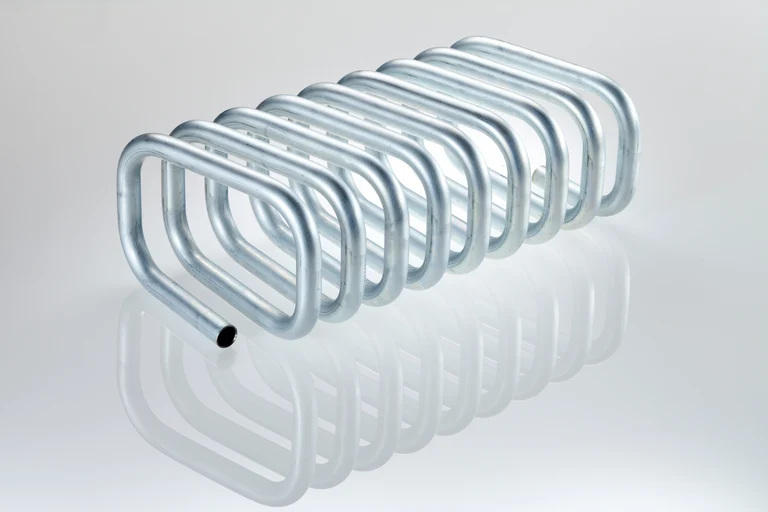

Production samples