NEWS:

We will keep you informed. Current news about products, fairs and projects can be found here.

Official KUKA System Partner

This close cooperation underlines our commitment to providing complete automation solutions for tube processing from a single source – from…

Meet us at the Blechexpo.

We will be attending Blechexpo Messe in Stuttgart again this year. From 21.10 to 24.10.2025 we will be in hall 1 at stand 1107 with our exhibition…

TubeTalk Episode 4

t motion: Big Impact. Small Footprint. In our latest TubeTalk video, Sharif and Felix present a automated tube processing cell in detail.

INCORRECT ASSEMBLY IMPOSSIBLE!

With the semi-automatic ORFS ring feeder, transfluid has developed a cost-effective solution for the safe and effective production of small, medium…

TubeTalk

We are pleased to invite you to our new series of videos explaining our products and production technology. 🎬

Shaping the flow of energy.

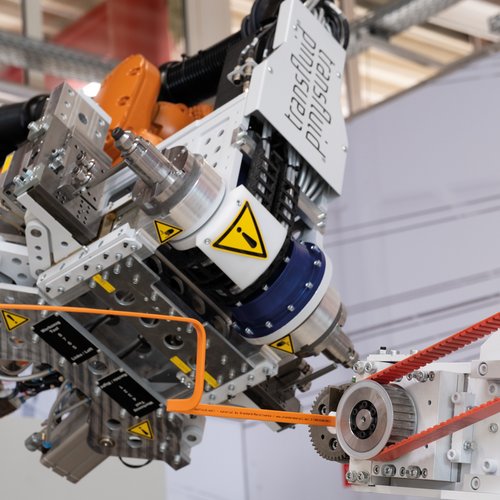

Extremely long busbars cut and bent automatically. Transfluid has developed a bending robot specially to meet the requirements for the production of…

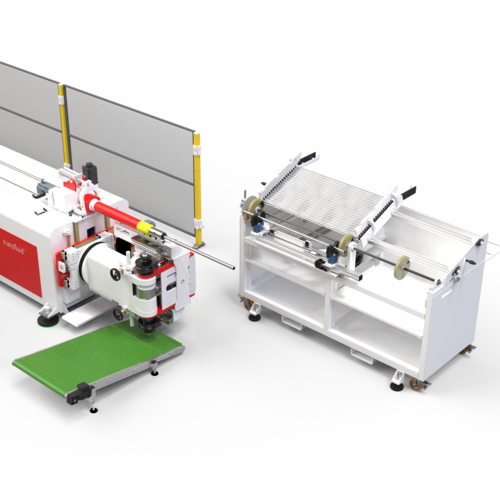

Cost efficient loading

To create even more flexibility especially for our cnc tube bending machines we designed an easy and less expensive loading unit.

Busbars & Solid-material

Shaping the flow of energy. The bending machines from transfluid are known for their performance in tube bending, but they can also be used to bend…

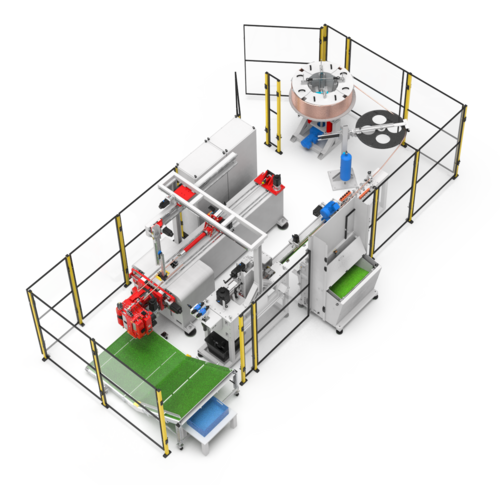

Compact manufacturing cell concept for fully automatic tube production

Due to the current demand in the field of renewable energies, especially with regard to heat pumps but also for domestic hot water systems, we have…

Get there fast with transfluid.

transfluid tube processing machinery Inc. becomes official sponsor of „Trick Tools Racing“ in the NHRA Pro Stock Motorcycle Series.

Partnership in the world of tubes

The partnership between TRUMPF and transfluid® enables highly flexible combinations between laser tube cutting systems and tube bending/forming…

Merry Christmas

And a happy new year. The time before and around Christmas is a good opportunity to pause for a moment and remember all the good things you have…

ABSOLUTE INNOVATION right/left bending up to ø 2 3/4"

With the new T bend CNC mandrel bending machines of the type DB 2060-CNC-R/L, steel, stainless steel and non-ferrous metal tubes can be bent as round…

TUBE DÜSSELDORF 2024

The wire and Tube - Leading International Trade Fairs - opens its doors again next Monday and we can't wait to welcome you to the world's leading…

"Global market Leader"

Another award for the "global market leader from South Westphalia". The award is given to international companies that are technology leaders and…

ALL GOOD THINGS COME IN THREES.

Highly flexible combination between laser tube cutting system and tube bending technology. Automated production of 12,000 different pipe geometries.