Our solution for your individual requirements

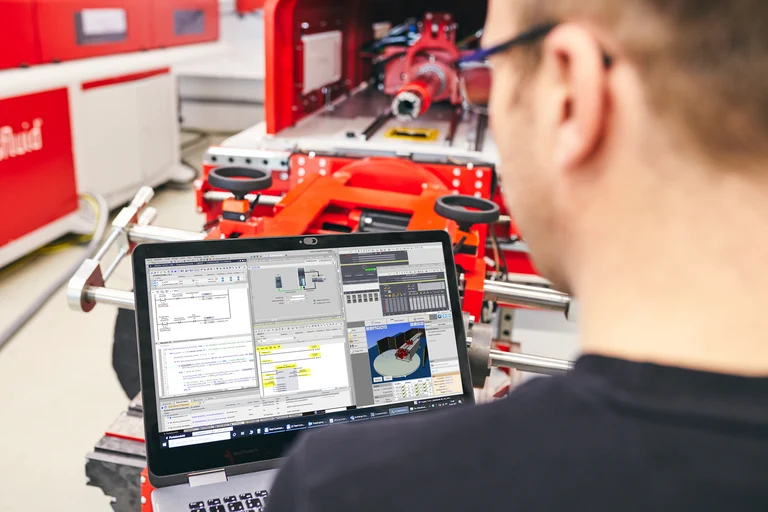

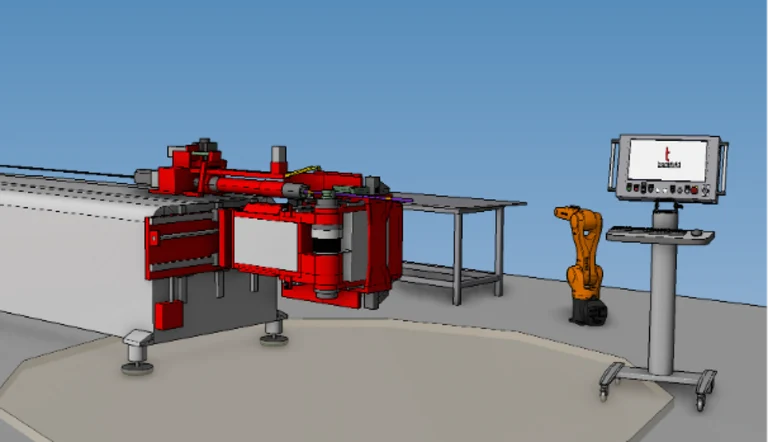

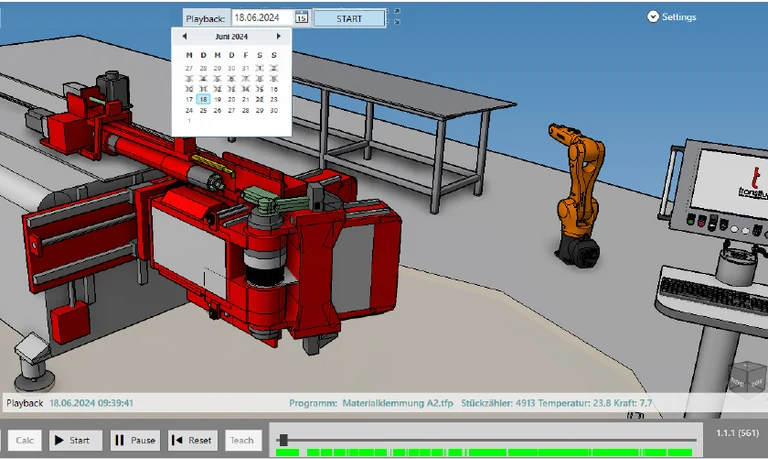

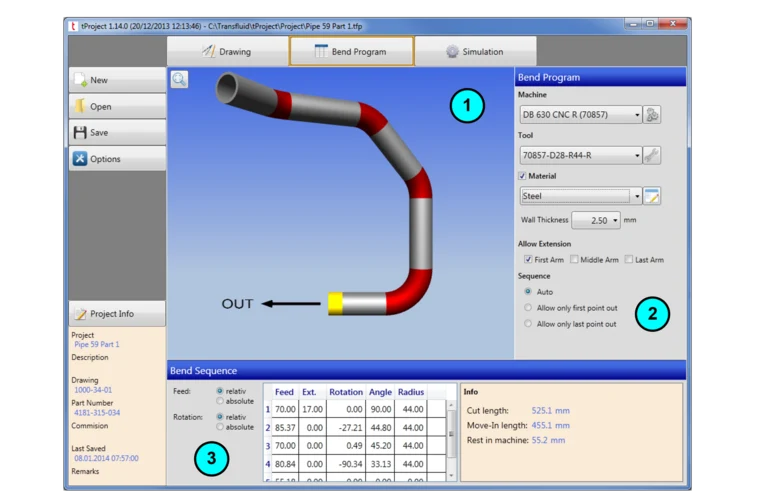

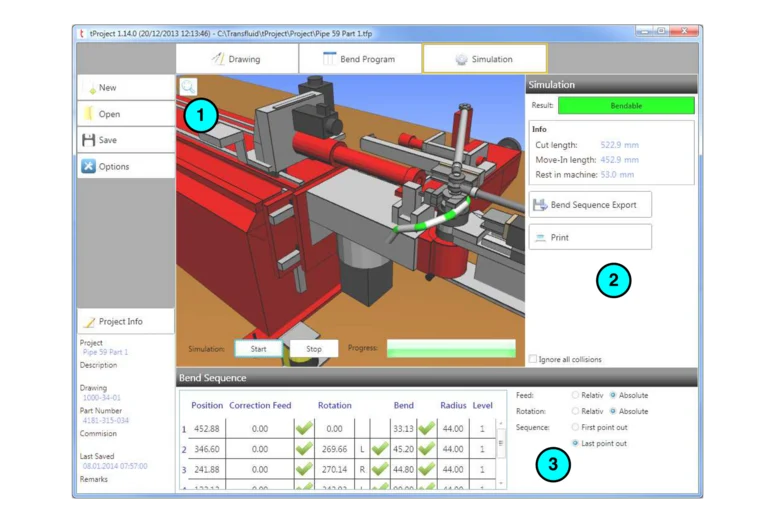

We have developed four versions of our t project software, which can be used as stand-alone or as networked versions. t project can be integrated centrally in the company's internal security system for optimum data security. Customer-specific modifications, expansions or interfaces are readily possible.