OUR EFFECTIVE TUBE PROCESSING WITH TIME AND COST BENEFITS.

For pipes up to diameter 330x25 mm

All materials and wall thicknesses can be processed

Mobile solutions for pipes up to 101.6 mm

All in one solutions for on-board piping incl. bending, screwing and sawing

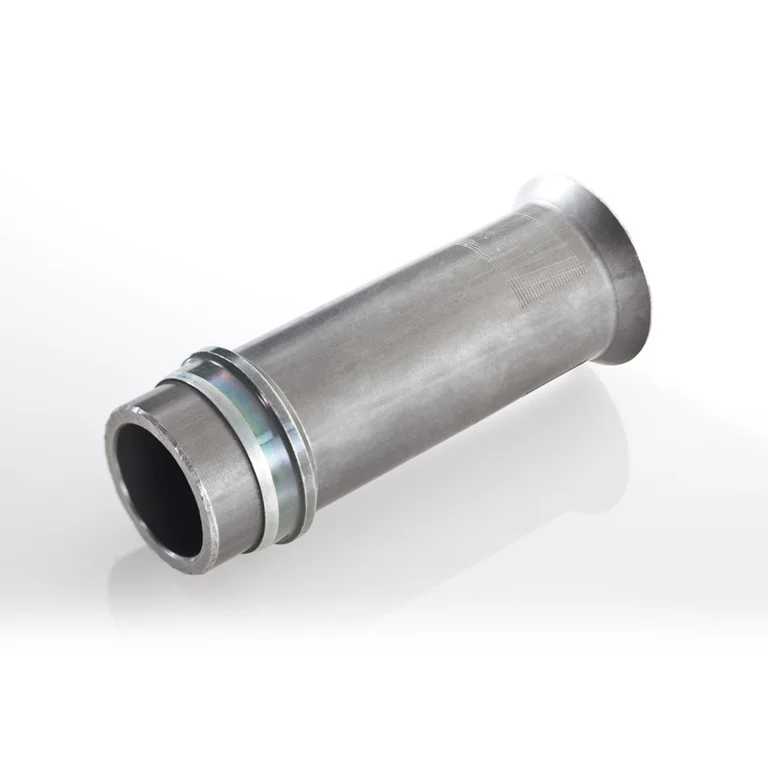

Expanding machine for easy lapping of pipes up to diameter 330 mm

PRODUCTION SAMPLES